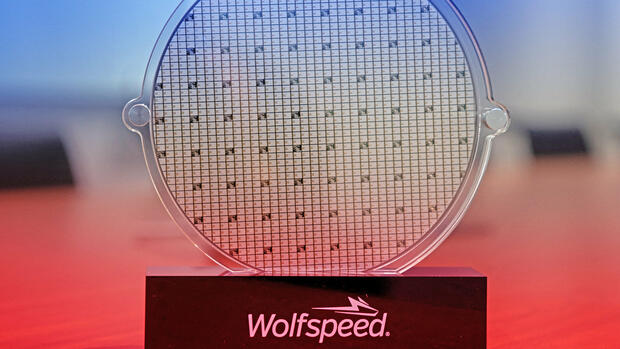

The US group Wolfspeed and the German automotive supplier ZF are building a development center for silicon carbide chips in the Nuremberg area.

(Photo: via REUTERS)

Munich The automotive supplier ZF and the American chip specialist Wolfspeed are investing again in Germany: The partners are jointly building a research and development center for semiconductors made of silicon carbide (SiC) in the Nuremberg area. The companies announced this on Wednesday. The two companies want to invest up to 300 million euros and create 150 jobs as a first step. In the long term, up to 1000 new jobs could be created.

In February, ZF and Wolfspeed had already decided to build a new chip factory for SiC chips in Saarland. Another development site is also to be built there. Construction work is scheduled to begin in both Saarland and Franconia in the course of the year. Bavaria’s Prime Minister Markus Söder announced that 130 million euros in state aid will flow into the settlement in Franconia.

Competitor Bosch invests in America

In the race for the best starting position at SiC, ZF and Wolfspeed follow suit. Because just last week, the automotive supplier Bosch announced that it would invest 1.5 billion dollars in a SiC factory in California. The Swabians already produce chips in their own factories in Reutlingen and Dresden.

The combination of silicon (Si) and carbon (C) is energy efficient and takes up little space. On average, the components are ten times smaller than conventional silicon chips and lose up to 50 percent less heat. SiC allows vehicle manufacturers to either use smaller batteries or offer a range that is a good 15 percent longer. However, SiC chips are also significantly more expensive.

>>Read here: Like US chip corporations Bind Mercedes and BMW

It is no coincidence that ZF and Wolfspeed are settling in the Nuremberg region. There is a lot of SiC know-how here. The only factory in Germany that produces the raw material SiC is in the north of the city. The plant belongs to the Japanese chip manufacturer Rohm. In addition, ZF’s power electronics competence center is located in Bavaria, said CEO Holger Klein in Munich. The group employs 18,000 people in Bavaria. “We need the best talent, resources and ideas that we can find,” said Wolfspeed boss Gregg Lowe, justifying the choice of location.

ZF does not rely solely on Wolfspeed

A huge market is tempting: market researchers at Yole expect the market for SiC chips to grow to six billion dollars by 2027, more than three times as much as in 2022. At the beginning of the next decade it should be ten billion.

However, ZF does not rely solely on the partnership with Wolfspeed. In mid-April, the foundation company from Lake Constance secured a second supplier for SiC chips in world market leader STMicroelectronics (ST). According to the company, a multi-year contract provides for ST to supply tens of millions of SiC modules.

More: The Linux of chip design: A new standard is revolutionizing the semiconductor industry