Did you know that we had a Jeep factory in Tuzla when domestic automobiles were so popular in our country’s agenda?

Although it existed, the sudden closure of this factory for the production of military-class jeeps still remains a mystery. The issue of why production was stopped even though the military vehicles produced are still used by the Turkish Armed Forces; public, press and those involved in the project It remains unclear even among experts.

While the sudden closure of the factory left question marks in the minds of many people at the time, todayMaybe today “We could have world brand Jeeps.” It makes you think.

Let’s explain from the beginning. Turkey’s significant share in the automotive industry led foreign manufacturers to want to produce domestically and to open automobile factories for a while.

While companies such as Toyota Türkiye, Oyak Renault and Tofaş produce passenger cars; Ford Otosan, Anadolu Isuzu and Mercedes Benz Türk Companies such as were producing commercial vehicles.

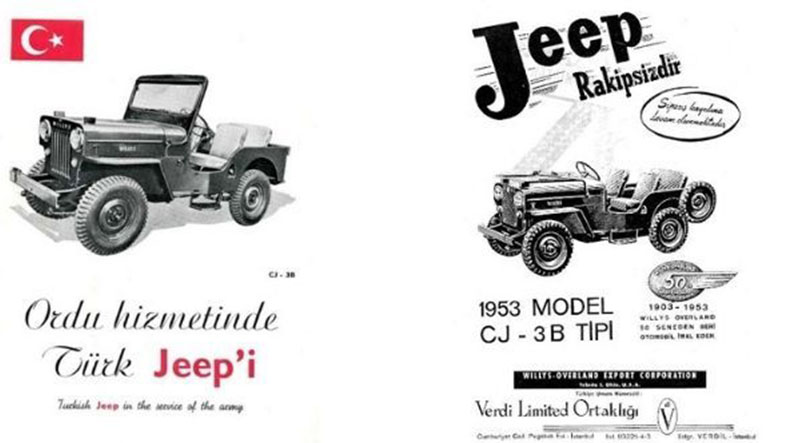

However, there was another company known as Turkey’s first domestic automobile factory: Turkish Willys Overland.

Turkish Willys Overland, founded in 1954 Tuzla Jeep Factory It was represented by . This factory completed the assembly of parts imported from America with parts produced in Turkey and produced civilian and military jeeps and pickup trucks.

The factory, which was transferred to the Turkish Armed Forces, started its localization project in 1986.

The localization project, initiated under the name ‘T Model’, was completed completely in 1990. It enabled the production of GT and GTD models. These models went into production in the 1990s as military-grade Jeeps.

by the Turkish Patent Institute in 1995 “Tuzla 1013” The factory, whose trademark was registered with its name and ‘T’ logo, made the models produced ready for export with the authorization received from the Ministry of Industry and Trade.

Tuzla Jeep Factory has produced 15 different models of vehicles to date.

These models included commander vehicles, personnel vehicles, weapons-loadable vehicles and ambulance jeeps. Locally produced models are more durable than imported models. He had the ability to climb steep slopes. Besides They were imported at only 20% of the price, and the power of the vehicles was many times greater than that of other world-famous brands.

Besides tools engine, transmission, off-road gears, differentials, shaftspowertrain and chassis were entirely manufactured at the Tuzla Jeep Factory.

1013. Ordu Equipment Main Repair Factory The factory, also known as , had a 100% local production rate.

So what happened after everything was good?

While everything was going well, in 2006 the factory “No need.” It was closed for the following reason. Although no clear statement has been made on the subject, Prof., a faculty member at the Department of Mechanical Engineering at Yıldız Technical University, who is part of the team at the factory. Rahmi Güçlü’s His statements draw attention on this issue.

Strong, throughout the time he worked in the factory a change of concept of the army He says he has heard that he plans to do so and will discontinue production.

Güçlü pointed out the difficulty of manufacturing and the tendency of industrialists to import. revolution cars He also emphasizes that many projects such as have been stopped for similar reasons and that this situation must be investigated.

The authorities did not know the reason for the closure.

Strong wombwhile explaining the process, answers the questions asked by saying that only high-level authorities and officials can give answers, and you need to ask them:

“An opinion was expressed that the army would make a concept change, exit the manufacturing sector and enter a different concept. In this factory production will be stoppedIn fact, the closure of the factory was already something that was constantly talked about. “While some people may be happy with this, others may be disturbed.”

The factory has strategic importance for both Türkiye and the Turkish Armed Forces. It is mind-boggling that it was such a huge project and it was suddenly stopped.

Moreover, Turkey has encountered such a ‘stoppage’ whenever it has taken steps towards domestic automobiles…

Powerful, produced jeep vehicles He also mentions the existence of countries such as Iran and Pakistan who want to buy by seeing it in the exercise. If production had continued, demands for civilian needs could have been met; We could have a world brand car. But it didn’t happen.

Even though the first thing that comes to our mind in our domestic automobile adventure is Devrim, which was stopped due to lack of gasoline, or Anadol, whose production was discontinued because the cows ate it, we see that the project belongs entirely to us. Tuzla 1013’s The reason for stopping is at a similar point to them.

This situation, Turkey’s domestic production potential in the automotive industry It leads us to think deeply about how it is prevented and why it is difficult to create a completely national automobile market in the country.

All that remains is domestic vehicle All we have to do is lose our production ability and become dependent on abroad again.

Our other content related to automobiles:

RELATED NEWS

Why Did Koç Holding Stop the Production of Anadol, Turkey’s First Mass-Produced Domestic Car?

RELATED NEWS

Our Domestic Car, Which We Can Never See on the Streets Because It Cannot Withstand the Pressure: “Zafer”

RELATED NEWS

Locally Produced Automobiles That Will Drift You in a Flood of Emotions (Contains Sports Anadol)

RELATED NEWS