Dusseldorf The energy industry is in transition. Gas crisis, record electricity prices and shortage of raw materials – one crisis message follows the next. But one crisis is another’s opportunity. At least that’s how Peter Geigle sees it. The boss of the German storage start-up CMBlu is convinced that the current situation will bring about a breakthrough for his technology.

“Lithium-ion storage prices have increased massively and that is very helpful for us. Storage must make energy supply cheaper, not more expensive,” says the founder of the greentech company from Alzey in Rhineland-Palatinate. This requires permanently cheap materials that do not make you dependent on one supplier. And this is exactly where Geigle sees the gap for organic redox flow batteries.

His company produces organic battery storage systems, i.e. those based on natural materials. Among other things, lignin is used, which ensures stability in plant cells. It occurs in large quantities, for example in paper production.

The cleantech company also calls its development a “solid flow battery”. It should be able to solve part of the storage problem, especially in view of the increasing share of renewable energies in electricity generation.

Top jobs of the day

Find the best jobs now and

be notified by email.

On Wednesday, CMBlu, together with the German energy supplier Uniper, announced the next step for its systems. In a joint field test, a battery with an initial size of one megawatt (MW) is to be connected to the grid on the site of the power plant operator in Großkrotzenburg in Hesse.

“The advantages of the solid-flow battery are obvious to us: In a direct combination with renewable systems, it can increase base load capacity on site, but direct connection to the energy market and to our customers for peak load smoothing is also possible,” explains Arne Hauner, Director of Innovation at Uniper, the cooperation.

Storage technology is booming – and is urgently needed

Because green energy sources such as the sun and wind are not always available when you need them, unlike coal-fired power or nuclear energy, storage technologies are needed that deliver electricity even when there is no wind and no sun is shining.

These are booming all over the world. Declining production costs, rising electricity prices and more and more wind and solar systems, coupled with the increasing number of electric cars, are among the key drivers.

Even if lithium-ion batteries are currently the most common storage variant, experts see other technologies on the rise in the long term. The redox flow battery is one of them. In contrast to a lithium-ion battery, liquid electrolytes are used in the storage devices, also known as “flow batteries”. There are two different liquids in each of two large tanks.

In between sits an energy converter with a thin membrane. During the charging process, the ions in one liquid release electrons, which then migrate through the membrane into the other liquid. The energy is thus stored chemically. If the electricity is needed again, the process is reversed and electrical energy is released. This process can be repeated any number of times.

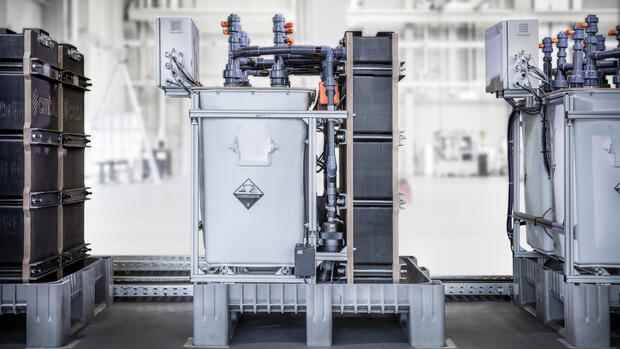

The Uniper power plant serves as a test site for the storage technology.

(Photo: dpa)

While lithium-ion storage can deliver a lot of energy within fractions of a second, redox flow batteries are less dynamic. When used correctly, however, they offer decisive advantages: memory size and performance can be scaled independently of one another and almost at will.

Experts see them as a good means of cushioning peak loads in the power grid. The energy can be stored for several hours and then quickly fed back into the grid when demand is very high.

Redox flow batteries could serve medium-term storage needs

Redox flow batteries could thus bridge the gap between lithium-ion batteries for short-term use, for example in cars or small home storage systems, and power-to-x projects, i.e. storing excess electricity in the form of green hydrogen, for a period of time of several days and weeks.

“We believe that solid flow batteries will play a more significant role. The costs over the entire lifetime of the battery are decisive for storing energy – and not the euro price per kilowatt hour,” explains Uniper manager Hauner.

For Uniper, it is also an opportunity to report something positive in the middle of the crisis. The energy company has been accumulating billions in losses for months due to the massive increase in gas prices and recently had to take advantage of state aid. “These are very special times for Uniper. But right now, transformation is more important than ever. On the electricity market, renewables must be produced as cheaply as possible, and storage technologies are the absolute core here,” emphasizes Hauner.

Above all, Uniper is providing its premises, the necessary grid connection and its experience for the project. In addition to the fossil power plants, the pilot plant will then be tested in countless injection and withdrawal cycles in order to simulate practical operation as realistically as possible. “We now have to get out of the laboratory and get on the net,” explains CMBlu founder Geigle.

In Asia and the USA, batteries have long been economical

The demand for redox flow batteries is growing. The proven storage technology has long occupied a large market in other countries. Flow batteries have long been on the market and economical in China, Japan, Korea and the USA.

There, however, the batteries usually run on the basis of the metal vanadium. Organic-based redox flow batteries, on the other hand, still have to prove themselves in long-term use.

In the Austrian Burgenland, too, a large pilot project started in May with the northern Bavarian river batteries. It is the largest non-lithium-based large-scale storage project in Europe and is intended to help make the region self-sufficient from fossil fuels by 2030.

Lithium-ion batteries are the biggest competitor for redox flow technology due to their massively reduced costs. However, due to the sharp increase in the price of many raw materials, including lithium, Geigle now sees a turning point: “The technology has reached the level of maturity where it can keep up with lithium in the industrial, large stationary area,” he is convinced. You stand on the threshold of a commercial product.

In Germany, however, only pilot projects have been running with redox flow batteries so far. But CMBlu wants to go into series production by 2025. The development partnership with Uniper is now the first real test for the cleantech company.

More: From restructuring case to crisis beneficiary: Record electricity prices ensure Steag’s profit jump