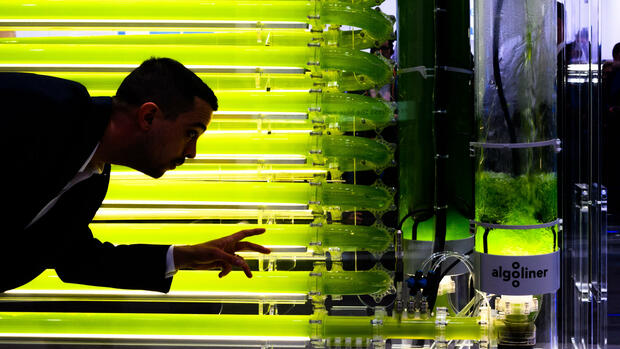

In the process, a large amount of carbon dioxide CO2 is bound and algae oil is produced. The oil can be used for cosmetics, food or fertilizers, for example.

(Photo: dpa)

Hanover Light green liquid flows through a meter-long tube and is exposed to artificial sunlight in an oversized test tube. This so-called bioreactor helps in the cultivation of algae, in which a large amount of carbon dioxide is bound. Algae oil is produced as a by-product, which can later be used as an ingredient in cosmetics or food, for example.

This biochemical process can be observed at the Hanover Fair at the Festo stand. The automation company developed the bioreactor together with researchers from the Bionic Learning Network. The result is a model factory with which Festo intends to advance the cultivation of biomass on an industrial scale – while conserving resources and without gases that are harmful to the climate.

“Our industry is heavily based on fossil resources,” says Nina Gaißert, describing the problem. She is an expert in bionics, i.e. the study of how phenomena from nature can be transferred to technology. Their goal: “What is currently made from petroleum, we can also make from algae.”

Read on now

Get access to this and every other article in the

Web and in our app free of charge for 4 weeks.

Further

Read on now

Get access to this and every other article in the

web and in our app.

Further