Even if we are not aware of it, almost all machines, big or small, that we use have a device called an encoder, and it converts machine movements into electrical signals and gives information about machine operation. Let’s take a closer look at what an encoder is, what it does, and how this device works.

Even when you open a simple device that you use at home, the complex structure that you see makes you understand how important engineering is. Machines developed by engineers have the purpose of fulfilling a specific function. The device that shows whether the machine performs the said function correctly is called an encoder. Almost all machines we use have an encoder.

It is possible to say a controller for the encoder. Because the only task of this device is to provide information by checking whether the machine in question is doing its job correctly and by converting machine movements into electrical signals. A good controller means that the machine does its job at its best. Bride What is an encoder, what does it do? Let’s take a closer look and see how this device works through its types.

What is an encoder?

The encoder is found in many different machines and It is a device that forms the basis of object control systems. The encoder converts the machine movements into electrical signals, detecting the position of the objects or whether they are in the right position, allowing the machine to do its job in the most accurate way.

What does the encoder do?

Encoder is a detection and control device. Let’s go through an example. When you get on the elevator, the encoder, What floor is the cabin on? and detects which floor to go to. Allows doors to open by recognizing if it is on the correct floor. In other words, whatever the function of the machine is and which objects it uses, the encoder controls the positioning of these objects.

An encoder is always in question, even if the detection and control function varies according to the machine it is used in. detecting the position, speed and direction of the object Checks if it is moving correctly. In other words, without an encoder, the rest of the machine can sometimes be non-functional because only this way can it be checked whether the machine is working correctly.

Encoder types:

- linear encoder

- rotary encoder

- Angle encoder

- Absolute and incremental encoder

linear encoder

linear encoder, detects linear object movements. Object movements moving over a path or line are controlled by a linear encoder. It is especially used in machines where length and cutting movements are in question.

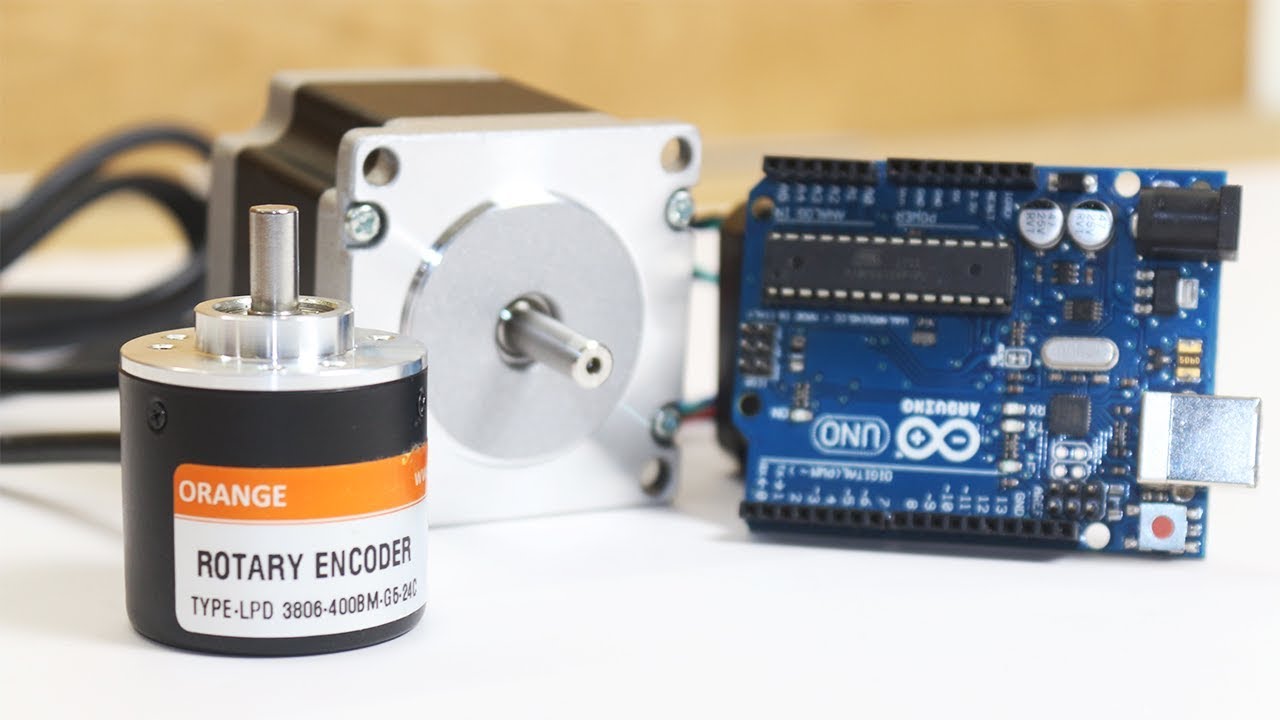

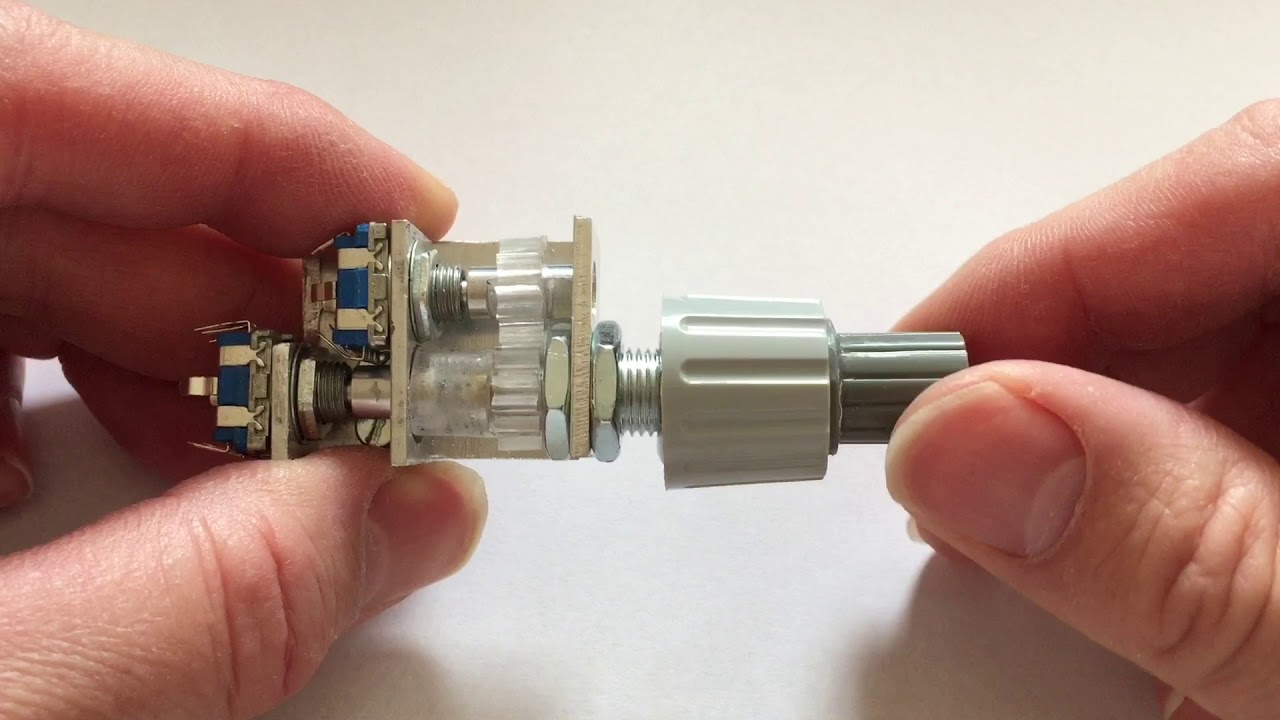

rotary encoder

rotary encoder, detects circular object movements. The object movements of the motors used in different vehicles and machines are controlled by the rotary encoder.

Angle encoder

Angle encoder, which has a similar sensing principle with the rotary encoder, also monitors the rotational movements and provides feedback. By Rotary encoder much more precise and detailed Since it provides feedback, it is used in suitable machines.

Absolute and incremental encoder

Absolute and incremental encoder detects both linear and circular object movements. However, there is a definite difference between them. absolute encoder, whether the object is in the correct position While controlling, the incremental encoder instantly follows the movements of the object. So absolute tells whether the object is in the right place; If incremental, it tells you where the object is.

Types according to encoder detection technologies:

- optical encoder

- magnetic encoder

- capacitive encoder

optical encoder

Optical encoder is the most commonly used and most accurate encoder type. It consists of light, opaque line and translucent disc. Light passing through the disc reaches the photosensor on the opposite side. An electrical signal is generated according to the presence of detected light.

magnetic encoder

Magnetic encoder detects through magnetic effects. It consists of a magnetic pole disk and a sensor. As the disk rotates, the sensor next to it monitors the object movements according to the magnetic field.

capacitive encoder

Capacitive encoder is one of the newest sensing technologies. It works on the principle of high frequency reference signal detection. It controls the return of the generated frequency by converting it into an electrical signal.

Encoder usage examples:

- In cutting machines, it starts the cutting process by telling the control device how much material is passed.

- It tells the mirror positions in the observatory.

- Provides precise motion feedback on railroad car lifting jacks.

- It starts the label printing process by detecting the bottle movements in the labeling machines.

- Reports the paper position on the printers.

- It shares the location information of bottles and jars in bottle and jar filling machines.

- It tells whether the correct floor has been reached in the elevator.

- Provides motion feedback on autonomous assembly lines.

It is possible to multiply such examples because wherever there is a movement and this movement is made by the machine by itself, there is an encoder. Thanks to encoder detection and monitoring All objects of the machine will make the correct movements and other objects will follow them.

It controls device operation by converting machine movements into electrical signals. What is an encoder, what does it do, what are the types We answered the frequently asked questions and talked about the details you need to know about the subject. It is truly admirable that a tiny device controls the entire operation of a huge machine.