Munich The shortage of skilled workers is increasingly accelerating automation, even in smaller companies, which have so far been rather skeptical about the use of robots. “The majority of our customers have no previous experience,” says Steffen Künstner, Managing Director of Jugard+Künstner (J+K), one of the largest cobot dealers in Germany.

The segment of collaborating helpers who can work right next to people has grown in recent years. According to the World Robotics Association (IFR), the cobot segment increased by 50 percent to 39,000 deliveries in 2021. According to industry experts, things should have continued to improve over the past year.

However, cobots are still a niche in the global robotics industry. “A few years ago I would have expected the breakthrough to come even faster,” says Enrico Krog Iversen of the Handelsblatt. The Dane once made the world market leader Universal Robots great as CEO and now wants to lower the hurdle for the use of cobots with the new platform D:Ploy, which was presented at the Hanover Fair. This should enable commissioning in just a few steps and without any programming effort.

According to Iversen, the fact that there is not yet a cobot in every factory and with every craftsman is mainly due to the fact that the companies have not taken the shortage of skilled workers seriously enough for a long time. But now the pressure to act is great, says Iversen.

According to a study by the Family Business Foundation, for example, a good 44 percent of industrial companies complain about a lack of specialist staff. According to the Institute of German Economics, the shortage of skilled workers in Germany reached a new high last year with 630,000 vacancies.

The purchase of a robot should pay off within a year

This increases the need for automation. The cobots were initially expensive and complicated to program, says J+K Managing Director Künstner. Both have changed in the meantime, for example a cobot for 40,000 euros will pay for itself in less than a year. J+K is one of the largest sales partners of the world market leader Universal Robots and has sold around 3000 cobots in the past ten years.

One of the new users is electronics specialist Turck, who installed their first cobot a good six months ago. Specialists are also not easy to find in the Erzgebirge district, and training temporary workers is often not easy. “We want to relieve our employees of monotonous activities,” says production specialist Enrico Becher.

Programming the cobot took a few hours, and after a week it was well integrated into the processes. Turck bought its second cobot a few weeks ago, so everything went a little faster.

Cobots can do that today

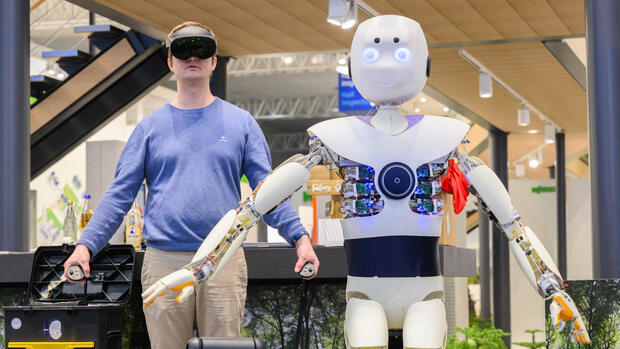

Heavy industrial robots, which have dominated the market for a long time, can, for example, do welding work in a car factory and balance the seats in the vehicle. The new collaborative robots significantly expand the possible uses, especially for smaller companies and craftsmen.

“A few years ago I would have expected the breakthrough to come even faster,” Iversen told Handelsblatt.

For example, the cobots can take electronic parts and place them in the right place (pick and place), polish wooden boards and stack boxes on a Euro pallet. The world’s largest robot manufacturer, Fanuc, has even developed a solution for bakeries together with oven manufacturer Wiesheu and retail specialist Wanzl. The cobot can fill the baking tray, put it in the oven and fill the displays before the staff arrives.

The fact that integration into everyday production is now easier is also due to the fact that a cobot ecosystem has emerged. When J+K recently inaugurated a new robotics center, many of them demonstrated the interaction. The robot arms come from Universal Robots, for example, grippers from Robotiq, for example, and companies like Waku Robotics help with the selection and compilation of the right hardware and software with the “Lots of Bots” platform.

The growth hopes of the industry could now be fulfilled. “The cobot segment will definitely grow larger than that of classic heavy industrial robots,” predicted Esben Östergaard, founder of robotics pioneer Universal Robots. For a long time, the Danes dominated the market that they themselves helped to create. According to industry estimates, they should still hold about 40 percent of the market.

Programming becomes easier: “We’ll do that in 20 seconds today”

Former UR CEO Iversen now wants to significantly expand the market. With the new D:Ploy platform, the initial installation of a palletizing application should only take four hours instead of the previous 40 hours. The solution can also be used to monitor operation and reprogram the robot. The platform recognizes the installed hardware and can define the robot movement.

“In the past, 700 to 800 cells of code had to be written to program a robot cell,” says Iversen. “Today we do that in 20 seconds.” The customer then only has to enter the size of the object and the pallet, programming and control then take place via the cloud.

The CEO of a large automation group gives the model opportunities. In recent years, the programming of individual robots has been simplified. However, this does not apply to the entire cell and the integration of the robots into the processes. Operating systems that are easy to use could help here.

>>Read here: Project Manufacturing-X: How SAP, Bosch and Siemens want to network industry

According to industry estimates, OnRobot – D:Ploy is just being rolled out – is currently generating sales in the low double-digit millions. “If things go well, we will be one of the central platforms in the future,” says the founder. In the medium term, revenues of 250 million euros are then planned.

Other companies are also working on simplifying the programming of cobots and applications. For example, Kuka has developed a uniform operating system that will be installed in all Group models over the next few years, starting with the cobots. Simple programming should thus become the standard.

The start-up RobCo has developed a kind of Lego kit for robots, especially for medium-sized companies. With this, different modules can be easily combined with each other. If the robot is then required for a new task, the modules should be easily reassembled and reconfigured.

More: This is how artificial intelligence is revolutionizing the industry