Dusseldorf Climate experts call it “the gray danger”: Concrete is one of the worst climate sinners. Almost eight percent of global greenhouse gas emissions can be traced back to the production of the most important component of the building material, cement. Emissions are higher than global computing power and air travel combined.

But the building material cannot be dispensed with. 3.8 tons of cement are used every year worldwide. With this amount, Germany’s entire infrastructure could be built about four times – every year.

Around 2.4 billion tons of CO2 are generated during production. And according to data from the think tank ACF Architects, the global demand for cement will increase by 20 percent by 2050.

Cement must therefore become climate-neutral as quickly as possible, especially since around 41 percent of the building material is used in infrastructure projects. To this end, companies and start-ups have developed innovations across the entire value-added process with which they want to counteract climate change.

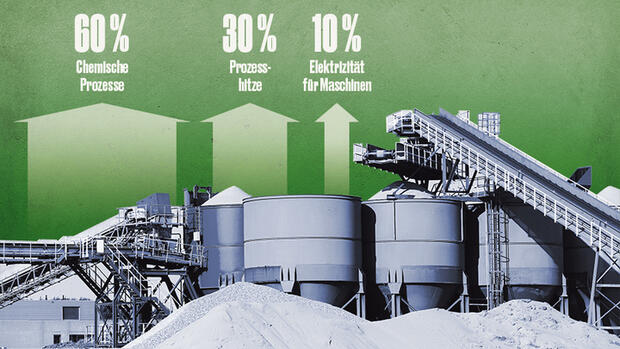

The binder consists of clay, sand, iron ore and limestone. The mixture is burned at around 1500 degrees Celsius to form the cement clinker required for the concrete. At 60 percent, the chemical reaction accounts for the largest part of the emissions, since the lime in particular releases a lot of bound CO2 during processing. The energy for heating accounts for 30 percent, the operation of the systems contributes another ten percent.

Manufacturer Holcim starts with this process. In one of its cement works in Lägerdorf in Schleswig-Holstein, the company wants to reduce CO2 emissions by 1.2 million tons of CO2 a year with new kiln technology. “The entire decarbonization of our industry only works if a lot of players talk to each other and look for solutions together,” explains Thorsten Hahn, Head of Holcim Germany, to the Handelsblatt.

Food grade CO2

“Oxyfuel” is the name of the new process used in the furnace prototype. In contrast to conventional cement kilns, it is to be operated with pure oxygen. “Usually, the furnaces are operated with ambient air,” explains Hahn.

However, in addition to oxygen, there are also other gases in this which are later excreted from the cement kiln as waste gases. The oxygen required for this comes from electrolysis projects in which industrial companies split water into hydrogen and oxygen using electricity from renewable energies.

“When cement is made with pure oxygen, the CO2 also becomes very pure and can then be split off and reused,” says Hahn. So it doesn’t escape into the atmosphere.

In the last step, the CO2 can be processed into methanol, for example, or processed as a raw material for the chemical industry to produce plastics, for example. It’s even food-grade—you could theoretically add it to soda or beer.

The production of cement is considered to be harmful to the climate.

(Photo: Moment/Getty Images)

According to Holcim, it works with Linde Engineering to treat the separated carbon dioxide. The plant cannot go into operation until 2029. Approval for construction is expected by the end of 2024. The EU is funding the climate-neutral cement plant with almost 110 million euros.

The method of splitting off CO2 and storing it for further processing is called “Carbon Capture and Usage” or “Carbon Capture and Utilization” (CCU). The legal framework for this is complicated in Germany: CO2 capture is primarily regulated by the Federal Immission Control Act, transport and storage by the Carbon Dioxide Storage Act. Since 2012, this has only permitted research into CO2 storage to a limited extent.

The US start-up Solidia Technologies offers an approach to storing the climate pollutant from the air in building materials. Instead of water, Solidia’s cement reacts with CO2. It binds the carbon, which holds the building material concrete together. Overall, Solidia can reduce the CO2 footprint by up to 70 percent.

More green ideas that could change the world

Prominent financiers believe in the project: The venture capital firm Kleiner Perkins Caufield & Byers and the chemical giant BASF are involved. The US Department of Energy also awarded the company a $2.1 million grant in 2022 to test climate-friendly manufacturing.

Another way of storing CO2 in cement is through recycling processes. Here demolition concrete is first crushed into granulate and then mixed with CO2. The concrete binds the carbon dioxide in the fine pores on its surface – and these are larger in the granulate than in the preliminary stage. The granules with the stored CO2 are fed into the production chain for fresh concrete, where they replace sand and gravel.

Pioneer in Switzerland

The ClimateTech company Neustark put seven plants into operation in Switzerland last year, in which granules are produced and mixed with CO2. “This week, the company’s eighth plant will go into operation, which can store more than 1000 tons of CO2 a year,” explains the company spokeswoman. Others are being planned, including a long-term project with a building materials company in Berlin.

Many Swiss companies already mix 60 percent of the granulate into their concrete – in Germany the average is just two percent. According to Neustark, there are many interested parties in Switzerland, Germany and across Europe, but ultimately it’s an up and down.

The innovations could be used faster and more extensively if there were a good CO2 infrastructure, criticizes ACF Architects. New plants that capture CO2 require significant investments to capture the CO2. In addition, the infrastructure for the transport and storage of the CO2 must be built beyond the plant. This must be done by the state rather than by the cement manufacturers themselves.

series “These green ideas could change the world“: From wave power plants, carbon-free cement and solar panels in space to energy-giving species of algae, there are ideas with the potential to change the world. Only a few make the breakthrough. We present some of the most interesting innovations. The series is scientifically supported by the independent think tank Future Cleantech Architects.

More: Climate neutrality: Millions of tons of CO2 underground