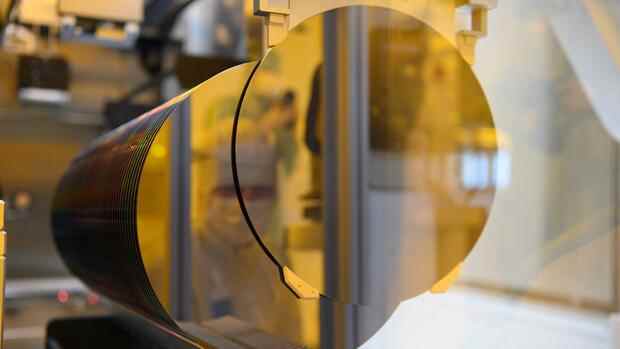

The chip business is booming and capacities are being used to full capacity worldwide.

(Photo: dpa)

Munich An ice storm, fire and the virus: the chip industry was spared nothing in 2021. First, the onset of winter in Texas prevented several semiconductor factories from operating, then a fire destroyed clean rooms in a factory in Japan. Most recently, Corona paralyzed important locations in Malaysia.

As if that weren’t bad enough, the recent lockdown in Xi’an, China, is currently having a massive impact on memory chip production at Samsung and Micron.

2022 can only get better. But even if there are no natural disasters and accidents and the consequences of the pandemic weaken, chips will remain scarce. Several months, sometimes even years, will pass before the urgently needed new plants are up and running. Customers therefore need good nerves, but above all creative concepts.

Otherwise, they will have to stop the production line in the future because components are missing, as was the case in 2021.

Top jobs of the day

Find the best jobs now and

be notified by email.

Because the huge demand for semiconductors will not change anytime soon. The digitization surge accelerated by Corona is becoming ever faster and more extensive – and in many areas of daily life it is only just beginning. The new capacities now planned in the chip factories will hardly be able to meet the demand.

A robust supply chain is a must

What shall we do? Anyone who processes chips should make sure that the supply chain is as robust as possible. A larger warehouse is just the beginning. Ideally, the components come from several plants from different suppliers on different continents.

In addition, the chip customers should develop cars, refrigerators or headphones in such a way that components from competing suppliers can be used without any problems. This can often be achieved with an operating system that is independent of the chip manufacturer.

Those who want to ensure the supply of chips should also get closer to the manufacturers and not just rely on their suppliers. Large corporations like car manufacturers should seriously consider getting involved financially.

You could participate in production lines at chip manufacturers or contract manufacturers in the semiconductor industry. That would also be an opportunity to stand out from the competition with individualized chips.

Of course, all of this has its price. But it is even more expensive to annoy customers because they cannot get their cars because components are missing. This is noticeable in the short term in sales and in the long term may leave deep scratches on the image of a provider.

In the new year, chip supply will therefore be at the top of the company’s agenda from day one.

More: Infineon board member Gassel warns: Chip shortage “could last until the end of 2022”.