At the beginning of the 19th century, the young Turkish Republic became a shining star that managed to get out of a global chaos. The real struggle for the betterment of Turkey began in the first years. In the second part of our article series titled “History of Domestic Production”, we take a closer look at the first aircraft factories in Turkey and the aircraft produced.

Air transportation is one of the newest modes of transportation on earth. When the Wright brothers’ experiment was successful in 1903, man learned that he could fly objects much heavier than air, again using air. About 11 years after the world met a new tool called the airplane, it began to fight with that tool.

The developments that took place in and before the First World War greatly damaged the Ottoman Empire. A more modern society, a much higher level of prosperity was needed. Innovations were now constantly coming to the Ottoman Empire from outside. The wars brought the end of the country, and the national struggle became a necessity. With the leadership of Mustafa Kemal Atatürk, a brand new understanding emerged. The Republic of Turkey had to develop with its veteran citizens who came out of the wars.

Atatürk at the Izmir Economy Congress “The real struggle for liberation has started now. If we do not manage ourselves in a short time, you will try to bring the enemies we poured into the sea to our country for their money” had warned. The year was 1924, just 2 years before the opening of the first aircraft factory.

In the second part of Webtekno’s new article series Domestic Production History, we take a closer look at Turkey’s aviation foundations.

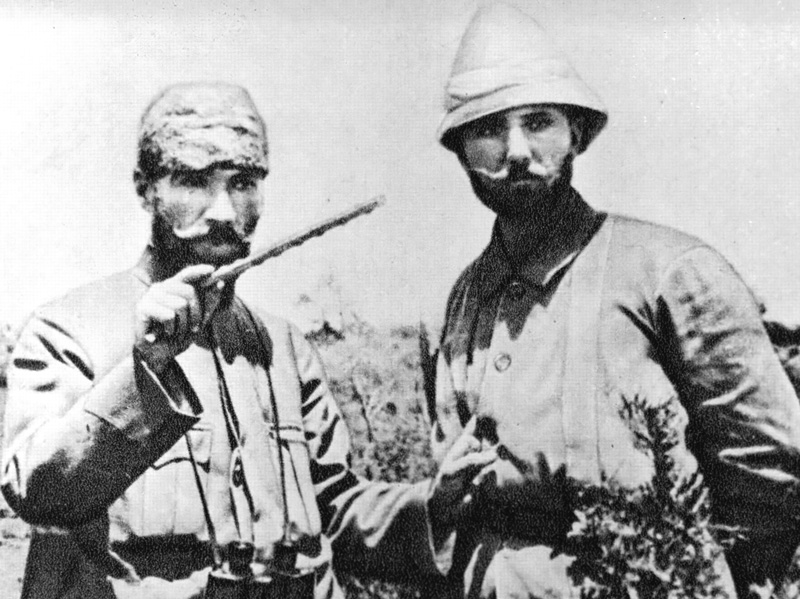

Mahmut Şevket Pasha, Süreyya İlmen, Enver Pasha and Major Ali Fethi Okyar, who were Atatürk’s comrades-in-arms and one of the founders of the young republic, played an important role in the execution of the first aircraft factory initiatives in Turkey. On the stage of history, the first nation to encounter planes on a battlefield was the Turks on the Tripoli front. The struggle for liberation, which continued with minor interruptions between 1911 and 1922, enabled us to witness many results of the changing world.

Mustafa Kemal and his friends gained an important knowledge on the strategic power of aircraft on the Tripoli front. Then, the power of planes emerged again in the Balkan Wars, Çanakkale and Iraq-Palestine fronts. While the total number of aircraft in the world was over 160 thousand before the war period, we had only 300 aircraft in the War of Independence. With the support received from Germany, this number could only reach 450.

It was not possible to produce airplanes immediately with the economy that was tired from the war. For this reason, the number of planes in young Turkey was very few in a significant part of the War of Independence. It had to be produced. On 13 June 1920, the foundations of the air force were laid, which later became the Turkish Air Force.

The first wings of the Republic:

It is known that in the last years of the Ottoman Empire, studies were carried out in different corners of the country for the production of aircraft. As a matter of fact, these efforts are inconclusive due to a collapsing economy and foreign-dependent production. The biggest factor in the Ottoman’s heavy blow in the First World War was its inadequacy in weather opposition.

The efforts for the economic, social and technological development of young Turkey had begun even before the end of the struggle for independence. The facilities established in our cities such as Kırıkkale during the war years, especially for the production of national war technologies, continued their production during the republican period. Producing airplanes was an industry in itself. Many technical components and parts had to be produced in different places with different techniques. A serious financial resource was required for this work. In the world of the period, although airplanes were produced by legal entities or companies, the customer had to be the state. A similar path had to be followed in Turkey.

Atatürk, who gave definite orders for the establishment of an aircraft factory in Kayseri 8 months after the establishment of the Turkish Aeronautical Association (February 16, 1925), was against the purchase of technology from outside. In fact, according to Atatürk, other countries wanted to sell technologies they saw as garbage, especially to countries in need, such as Turkey. Atatürk’s statement on the subject, which is engraved in our memories with every word, is as follows:

“As long as we do not bring the newest technology, not the obsolete ones, to the country, we cannot avoid being dependent on foreign countries. For this, we will carry the newest of modern technologies to our lands by tightening the belts as much as possible, roasting with our own oil, while creating new financial resources. One has to be either blind or stupid not to understand the cunning of foreign states who have brought the old technologies to us by giving us conveniences.

“Look at this war equipment industry that has developed in a short time… As soon as the First World War ended, all the weapons used in these dark days suddenly became obsolete. The Germans, the French, the British, and the Americans are trying to sell these weapons factories in their hands to underdeveloped countries by giving them long terms. Why? Because they are busy building factories that can make more modern ones, more effective ones. You can extend this to any area. Textile industry, pharmaceutical industry, automotive industry; in short, in every field that comes to mind… We are establishing a new and young Turkey. Friendly and enemy countries are left behind, we don’t need their technology. Either we build the newest one and compete with them, or we wait a little longer and wait until we have the strength to do it.”

An opportunity arose that would strengthen Turkey’s hand in aircraft production. Due to the Treaty of Versailles signed at the end of the First World War, Germany could not produce aircraft within its borders. For this reason, it was of strategic importance to contribute to the industries of independent countries. Turkey and Germany had common interests in aircraft production. The German company Junkers was known for its successful work abroad in aircraft production.

Cargoes and loads pulled by camels; Kayseri, Eskişehir and Aircraft and Motor Turkish Joint Stock Company:

According to the agreement made with the German company Junkers, the parties would make an equal investment of 3.5 million liras. The factory planned to be established in Kayseri under the contract was aimed at producing 250 aircraft per year. In time, problems started to arise between Turkey and Junkers. The company went into crisis because aircraft production was banned in Germany, and the German delegations did not give instant notifications to Turkey about the situation. Junkers could not make the 3.5 million TL payment, which was 7 million Marks. A new company was established, patent agreements were made, and it was aimed not to interrupt the works.

The headquarters of the new company, which is a Turkish-German partnership, was determined in Ankara. The company was named Aircraft and Motor Türk Anonim Şirketi (TOMTAŞ). Work for the aircraft factory in Kayseri continued from where it left off. Simultaneously, an aircraft maintenance-repair center was established in Eskişehir.

In a parliamentary speech made by Atatürk in 1924, he was walking confidently towards his goal of owning 1000 modern aircraft in 4 years. The state budget was around 100 million TL at that time, so the investment of 1,750,000 TL for the aircraft factory alone was a very high amount compared to the conditions of the period. Despite this, the Ministry of National Defense reached an agreement on providing an appropriation of 150 million liras. Yes, the budget in question was more than the money in the state’s coffers.

In accordance with the agreements made with Junker, aircraft parts and the needs of the factory and repair centers would be brought from Germany. First, the cargoes brought to the port of Iskenderun by sea were transported to Ulukışla district in Niğde by train. Camels, oxcarts and humans took over the loads. The roads between Ulukışla and Kayseri were crossed with great difficulty. In the autumn of 1926, work on the repair facilities should begin, and in 1927 production at the factory should begin.

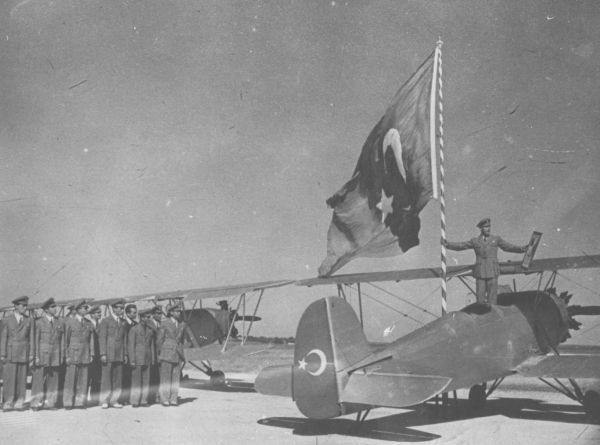

On October 6, 1926, TOMSAŞ was inaugurated with a state ceremony. The opening delegation went to Kayseri by plane from Ankara. 50 Turks to work in the factory went to Germany and received training. The problem of education, one of the biggest problems of the period, was tried to be solved by orientation studies carried out abroad.

The A-20, F-13 and G-23 aircraft, which were popular aircraft of the period in the Turkish Air Force, were now repairable at the center in Eskişehir.

TOMSAŞ had to stop its activities when the necessary resources could not be arranged, especially due to the hidden economic crisis of the Junker company. In addition, the salary differences between German and Turkish personnel caused unrest in the working environment. Turkish Aeronautical Association took over TOMSAŞ with all its R&D studies. The factory was overhauled until 1930, and in 1931, it returned to operation under the Air Undersecretariat of the Ministry of National Defense. Although the produced aircraft were backward compared to the technology of the period, they were very important.

Atatürk watches test flights in Kayseri

Until 1935, 50 gliders of three different types were produced for the Türk Kuşu at the Kayseri Aircraft Factory. As a result of the agreement made with the German company Gothaer Waggon Fabrik in 1937, 45 Gotha 145 units were produced. Over time, the factory gained a capacity to produce 4 aircraft per month. Other airplanes and models produced at the Factory are as follows:

- 30 pieces of A-20 L,

- 3 F-13s,

- 24 Hawk-II,

- 8 Fledgling 2C1,

- 43 Gotha 145 A,

- 45 pieces of Gotha 145,

- 4 PZL-24 A,

- 21 pieces of P-24 G,

- 11 US-4,

- 11 PS-2s

- 5 G-9s

- 77 gliders of three different types.

The last aircraft produced in Kayseri was the British Miles Magister type aircraft. In the following years, production was abandoned due to the fact that the USA sold a large number of aircraft to Turkey. The decision was a complete failure. Obviously, aircraft production in the country was stopped and we were forced to use the planes sold by the USA.

In the following years, it was ensured that the factory in Kayseri would continue to be used for maintenance and repair works. Many foreign companies, especially German companies, II. Until World War II, they applied to produce aircraft in Kayseri. Maybe if production had continued in that factory, Turkey would not have foreign dependency on the defense industry today. Perhaps aircraft production with original designs would be continued in that factory, and these aircraft could be sold to different countries.

The failure of TOMSAŞ to continue its production life went down in history as a major failure. Until the Blue Light project in 1978, factories and facilities were used for maintenance and repair works. Official activities of our army continue in the area renamed as Kayseri Air Supply and Maintenance Center with the project.