A major electricity transformation is taking place all over the world. When we look at the investments made especially in European countries, we see that it has been decided to establish a battery production factory almost every 200 kilometers. This situation gave very similar results in Turkey. First, Togg and its Chinese business partner Farasis, then ASPİLSAN, and now a new battery production facility by Koç Holding, Korean and Ford.

Koç Holding, Korean and Ford are establishing a battery production facility!

When we look at the facilities established in Europe, we see that many companies and automotive giants from Tesla’s Gigafactory to Panasonic, from Volvo to Samsung and from Varta to Volkswagen are rolling up their sleeves for battery production.

Of course, not all of these facilities have the same capacity. For example, 3 new factories are expected to be established in France. These are Envision, which will produce 2.5 GWh, Verkor, which will produce 16 GWh, and Acc. Similar tables exist in other countries as well.

Of course, we have to set aside Germany as an exception. Because 13 different companies are planning to invest here. Moreover, among them, there are those who roll up their sleeves for annual 40 GWh battery production, such as Tesla. A similar situation is taking place in our country.

In less than a year, 3 different companies confirmed that they will establish facilities in Turkey. ASPİLSAN even started production. On the Togg side, we see that there are long-term but ground-proof and very important plans for the future of automobiles.

Now, it has been announced that a battery production facility will be established by Koç, Ford and Korean with a capacity of 30 to 45 GWh per year. Togg and Farasis, on the other hand, will start operating with its facility reaching a production capacity of around 15 GWh per year as of 2025.

Therefore, the fact that the whole world has started the electric transformation in every field, especially in automobiles, is one of the reasons that triggered this situation. However, although it is a very profitable business in the long run, it is quite costly in the short run (as in the Koç and Ford duo). So much so that the cost of this new facility to be opened in Ankara has exceeded 2 billion dollars.

A pleasing development in battery production for Togg

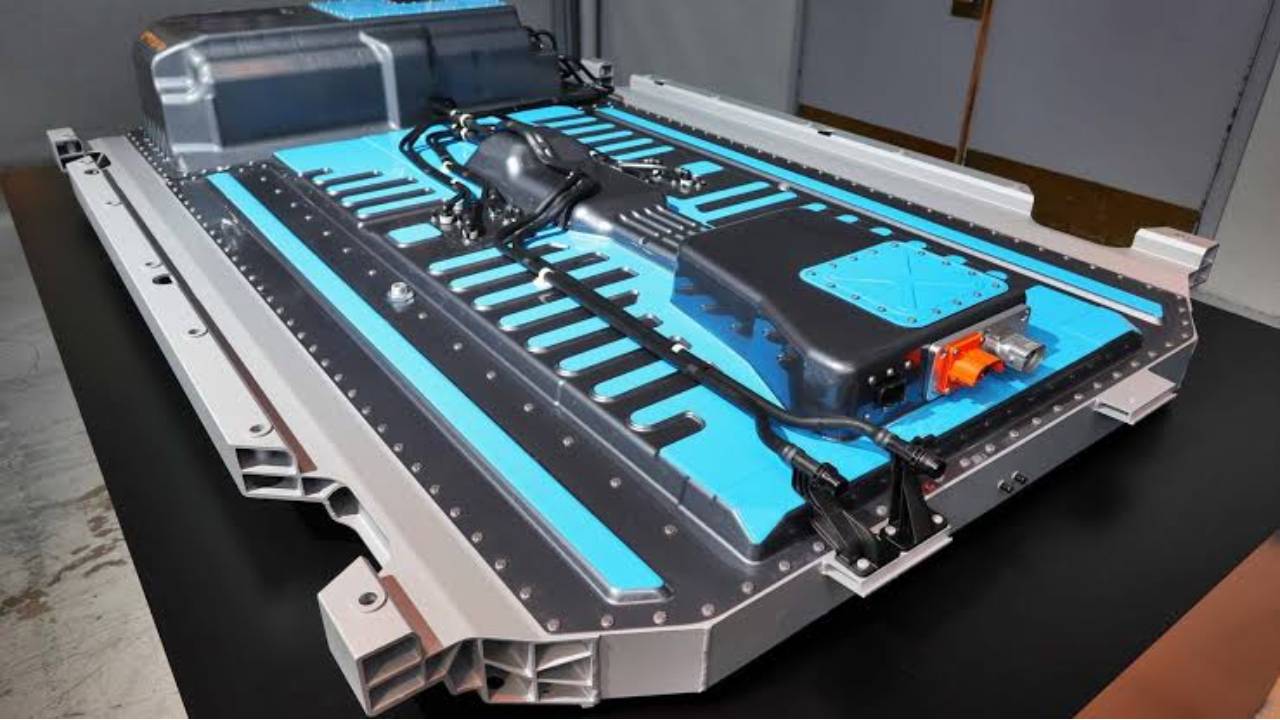

Togg had previously reached an agreement with the Chinese company Farasis on battery production. It was said that Siro, which was established as a result of this, will produce 15 gigawatt-hour battery cells and modules. Now, some information about the technical features of these batteries has been announced.

According to the news, the Chinese company Farasis, which is Togg’s partner in battery production, will produce its new generation batteries, which can go 250 km with an 8-minute charge (80%+ filling) and offer 1.5 million km of life, at Siro’s Gemlik facilities. However, the integration of the fourth generation, new type batteries, into Togg vehicles will be in 2025.

However, it should be noted that the batteries to be used in Togg’s first vehicles are also at a good point in market standards. Because it will be able to fill 80 percent in 30 minutes. Of course, let’s also say that the model mentioned in these data is not a 500, but a 300 km range model. However, the fact that this period will decrease to almost 1 in 4 in 2 years is quite a development.

In addition, according to a statement made by the Minister of Energy and Natural Resources, Fatih Dönmez, lithium ion battery production will be possible with lithium carbonate produced by liquid boron wastes in the coming period. The explanation on the subject is as follows:

We signed a cooperation protocol with Aspilsan and Aselsan for the use of lithium carbonate produced by Eti Maden from liquid boron waste in the production of lithium ion batteries. Domestic lithium will hopefully be the power source of domestic technology. There may be a new good news in 2022.

What do you think about this subject? Don’t forget to share your views with us in the comments!