Engine production, which has been the subject of discussion in Turkey for many years, is among the most frequently asked and curious questions to us. Important defense industry companies such as TEI can manufacture aircraft, helicopters, missiles and UAV engines.

However, it is not known how it is made, whether it is under license or with original projects, and in which aircraft or missiles it is used. At the Saha Expo fair, TEI General Manager and Chairman of the Board Prof. Dr. We talked to Mahmut F. Aksit about this issue. Here are the domestic engines produced by TEI…

Domestic engines produced by TEI!

Turkey has been trying to become a self-sufficient country in the defense industry for a long time, in other words, to meet its critical needs. In fact, this target dates back to its founding 99 years ago, even much earlier. But history is a different matter.

Currently, Turkey can manufacture both piston and jet engines with the great contributions of the private sector and technology transfers. Here, TEI (TUSAŞ Engine Industry), which is under the roof of TUSAŞ, comes to the fore.

TEI is under the license agreement of General Electric’s F110 engine, which has been used in F-16s for a long time. It carries out assembly, testing and repair activities from a to z. It can provide services not only to Turkey, but also to countries such as Oman and Saudi Arabia. In fact, we know that he has touched more than 325 F110s in this context, so he has a great knowledge from this project.

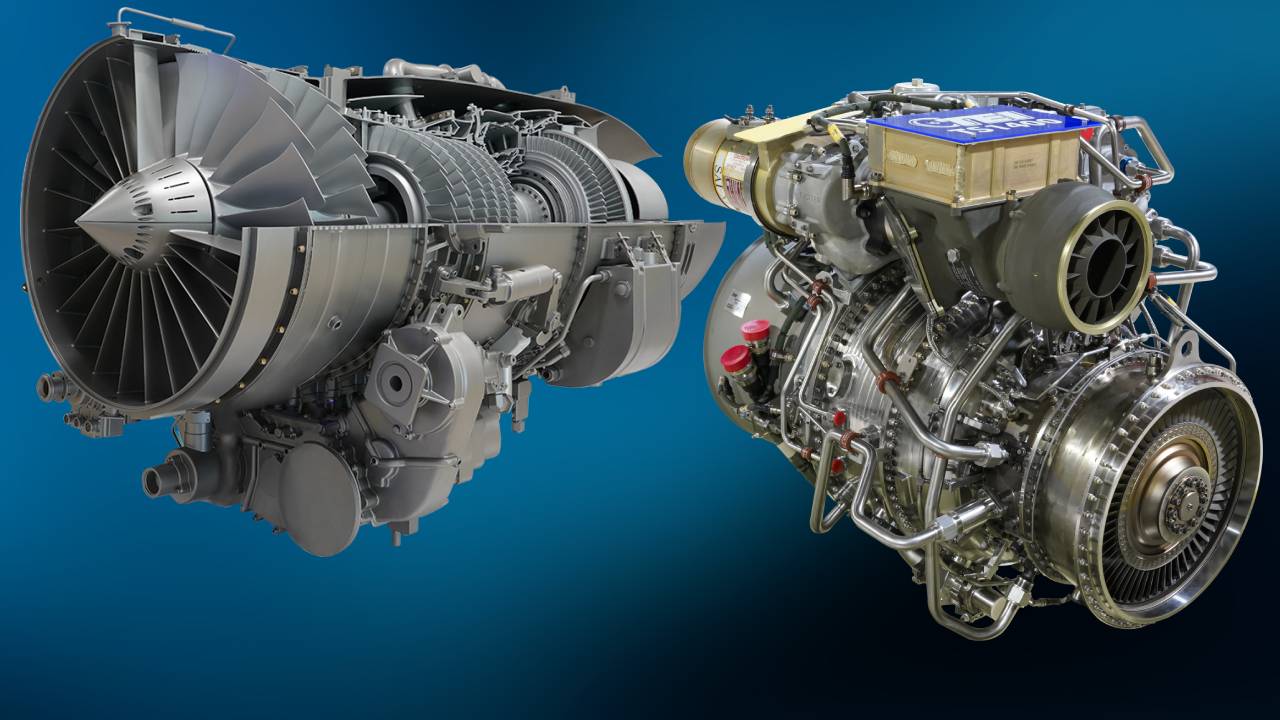

Of course, there are several similar projects. For example, it can produce the T700-GE-701D engine of General Electric Aviation, which powers different helicopters from AH-64 Apache helicopters to MH-60M Black Hawk, with its own configurations as T700-TEI-701D. In other words, it can go one step beyond assembly and do many things from spare parts production.

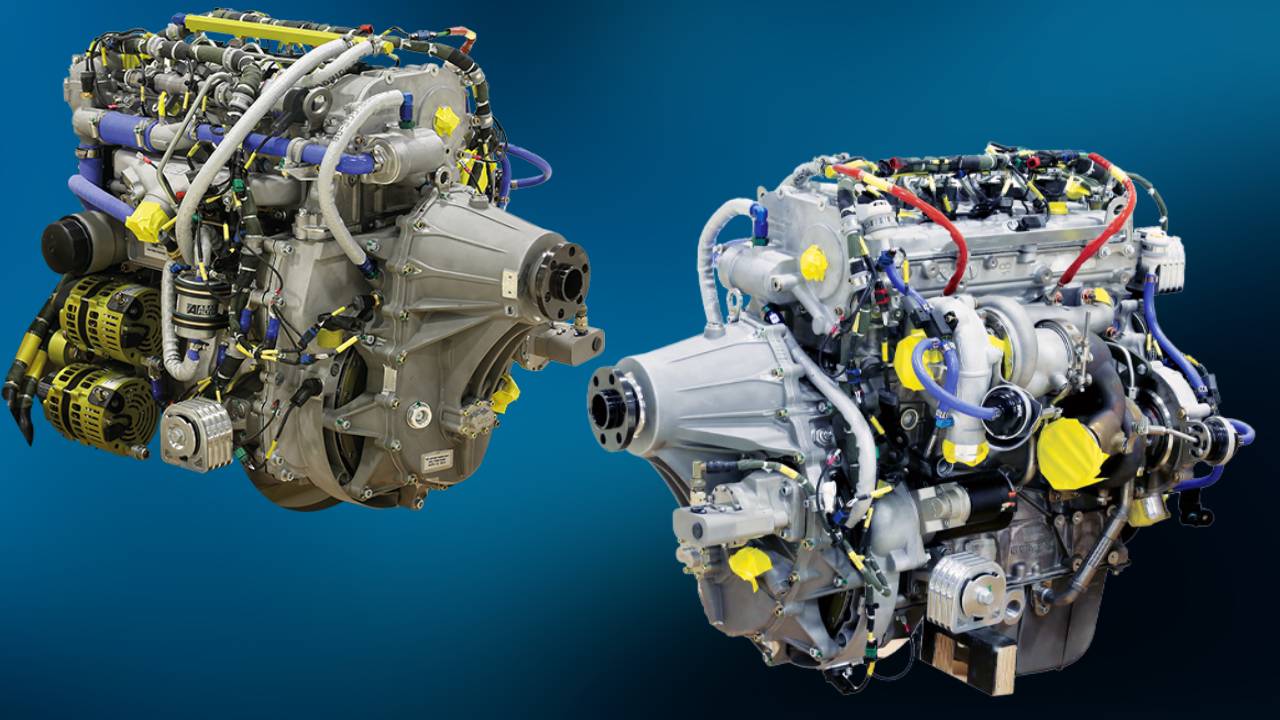

However, as we have mentioned, these are works done under license. In addition to these, there are 11 domestic and national engine projects that are currently running, original and whose license rights are in the hands of TEI. The most well-known among them is the ANKA and Bayraktar TB2 SİHAs (40+ units, the number is increasing) TEI-PD170 turbo diesel aviation engine.

To briefly mention the others, TEI-TF6000, TEI-TS1400 (Turboshaft engine to be used in Gökbey helicopter), TEI-PD180ST, TEI-PD222ST (We will see in Anka-S, Akıncı, TB3, and Aksungur), TEI-TJ300 (Medium-range anti-ship missile engine), TEI-TJ90, TEI-PG50, TEI-PG50S, TEI-TP38 and TEI-TJ35 a total of 12 (TEI-TF6000 still in production phase) project exists.

Some of these projects have been implemented and are now effectively used in field aircraft and missiles. Some of them have passed the testing phase and are waiting for the assembly process to the vehicle they will be used in. But apart from these, there are those whose foundations have just been laid and those who have not yet found resources.

For example, TEI General Manager Prof. Dr. Mahmut Faruk Akşit said that they are at a level to develop an engine for the National Combat Aircraft that can produce the same power as the Pratt & Whitney F119 (F119-PW-100 variant) engine used in the F-22, that is, with a thrust of 35,000 pounds.

However, a source has not yet been given for the engine specified by Akşit and the team has not been established. In any case, this resource we are talking about is not something that can be transferred overnight. So much so that even US companies, which have been doing this for 50 years, sacrifice at least 2-3 billion dollars when they try to develop a new engine.

If we look at the Turkish case, we can clearly see that public and private companies can and do make engines. However, as we mentioned, making an engine on a special order for a possible aircraft requires 5-10 years and billions of dollars in resources.

For this reason, we can say that the reason why domestic engine integration cannot be done from the first day in every project developed at the moment is that it cannot be met in terms of both time (the urgent needs of the TAF) and cost (Turkey’s economic situation). However, we can clearly see that the technological level has been reached.

What do you think about the domestic engines produced by TEI? Don’t forget to share your views with us in the comments!

shiftdelete.net

shiftdelete.net